Carbon Hinges & Swinging Doors

Here's a little tour of the process I used for making my composite hinges and doors. My favorite feature is the locking mechanism. I spent a lot of time thinking about this design, and I'm pretty proud of the result.

My objectives were as follows:

- Utilize swinging doors, rather than hatch boards.

- Make doors tightly stackable for storage.

- Avoid any protruding large latches or handles.

- Include a comfortable top step for sitting in companionway.

- Be lockable.

I surfaced some PVC core down to the desired thickness, bagged a panel, and cut both the outline, and the core rebate on the CNC, using a Rockler bit designed for cutting keyholes.

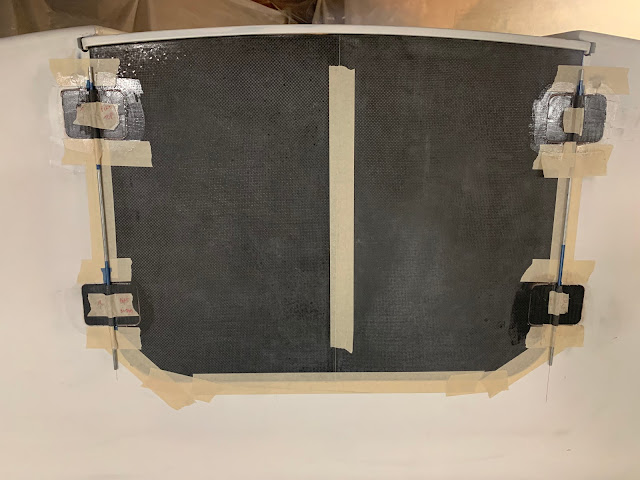

To get everything aligned was tricky, but not impossible. In this pic, one can see the full-length hinge pins, and copious amounts of masking tape to hold things still. I'm also using some flash tape to keep the pins clean, and a few playing cards form the backside, as they are the world's best shim stock.

This seems promising. I'll drop another post with a video showing the function.

Comments